Home > Progressive Cavity Pump

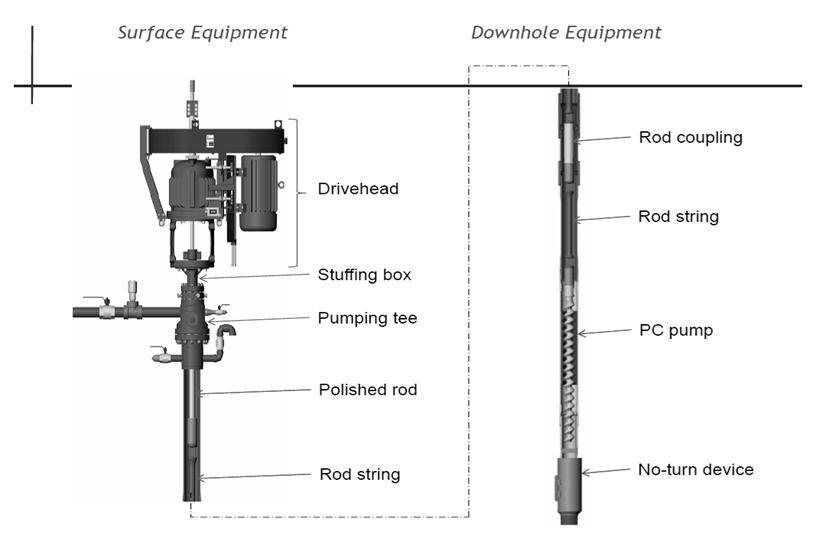

Ground-driven oil production cavity pump is an efficient, energy-saving oil production equipment, mainly composed of two parts, the ground drive unit and the downhole cavity pump. The ground drive unit transmits the wellhead power to the downhole through the rotary motion of the sucker rod and drives the downhole cavity pump to work.

Surface Drive

The surface drive is a specific facility to suspend and rotate the sucker rod, which in turn drives the PC pump. Then fluid can be brought to the surface by the continuous movement of rotor within stator. When the unit is stop, the surface drive head absorbs reversion torque and prevents thread off.

Surface Drive (Single Motor)

|

1-Stuffing Box |

2- Protective Mesh |

3- Main Support |

4- Support Framework |

|

5- Belt Guard |

6- PR Protective Mesh |

7- Clamp |

8- Bearing Box |

|

9- Pulley |

10-Motor |

11- Motor Base Plate |

12- Lifting Point |

Surface Drive (Dual Motor)

|

1- Stuffing Box |

2- Support Framework |

3-Motor (Dual-Motor) |

4-Belt Guard and Pulley |

|

5-PR Protective Mesh |

6- Clamp |

7-Bearing Box (Built-in brake system) |

8-Motor Base Plate (Adjustable) |

RTM Series Surface Drive Specification

|

Model |

Polished Rod Specification |

Max. Output Torque |

Bearing Axial Load |

Size |

Notes |

|

RTM1000 |

1 ¼-in. or 1 ½-in. |

1350 N.m |

12 T |

1200×750×1400 |

Single motor drive |

|

RTM1500 |

1 ¼-in. or 1 ½-in. |

2030 N.m |

18 T |

1330×845×1500 |

Single motor drive |

|

RTM2000 |

1 ¼-in. or 1 ½-in. |

2700 N.m |

22T |

1540×890×1750 |

Single motor drive |

|

RTM2000XL |

1 ¼-in. or 1 ½-in. |

2700 N.m |

30T |

1540×890×1750 |

Single motor drive |

|

RTM2000D |

1 ¼-in. or 1 ½-in. |

5060 N.m |

22 T/30T |

1940×1040×1750 |

Dual motor drive |

|

RTM3750D |

1 ½-in. |

5060 N.m |

30 T |

1940×1040×1750 |

Dual motor drive |

VED Series Surface Drive Specification

|

Item |

VED1000 |

VED1500 |

VED2000 |

VED2000XL |

Remark |

|

|

Maximum Output Torque (ft·lb/N·m) |

1000/1350 |

1500/2030 |

2000/2700 |

2000/27000 |

|

|

|

Maximum Output Speed (rpm) |

600 |

Different speed can be selected |

||||

|

Maximum Axial Load (Lb/kN) |

30000/150 |

39600/180 |

48500/220 |

66000/30 |

|

|

|

Maximum Base of Motor (IEC/NEMA) |

IEC 200L/ NEMA 326T |

IEC 250M/ NEMA 405T |

IEC 280M/ NEMA 445T |

IEC 280M/ NEMA 445T |

|

|

|

Motor Installation Mode |

Vertical motor shaft up, V5 |

|

||||

|

Motor Protection |

IP54/55 |

selectable |

||||

|

Motor Explosion-proof |

EXDIIBT4 |

claimable |

||||

|

Matching Motor Speed(rpm)@60Hz/50Hz |

1160/960 |

4P/6P/8P |

||||

|

Rod Specification |

1 ¼-in. or 1 ½-in |

1 ¼-in. or 1 ½-in or larger |

customizable |

|||

|

Power Type |

Motor 0r internal combustion engine |

default motor |

||||

|

Power |

3~, 50Hz, 380V Or 3~, 60Hz, 460V |

customizable |

||||

|

Spindle Type |

hollow spindle |

|

||||

|

Spindle Diameter |

2-3/4” (Φ70) |

|

||||

|

Driving Belt Pulley Specifications(in/mm) |

6in (150)/7in (180)/8in (200)/9-5/8(244) |

claimable |

||||

|

Driven Pulley Specification(in/mm) |

22in (560)/24.8in (630)/28in (710)/31.5(800) |

claimable |

||||

|

Maximum Deceleration Ratio |

5.1 |

|

||||

|

Break Method |

Wet centrifugal brake |

|

||||

|

Box Heat Dissipation |

Ribbed radiator |

|

||||

|

Connection Mode Between Rod and Drive Shaft |

6 screw or 8 screw rod clamps |

|

||||

|

Rod Sealing |

Stuffing |

|

||||

|

Stuffing Material |

PTEE / Graphite carbon fiber |

|

||||

|

Stuffing Box Bottom Connection |

73/89EU pin,3-1/8 3000PSI,2-9/16 3000PSI |

customizable |

||||

|

Rod Sealing BOP |

Optional single or double ram, take out port, etc., to adapt to the smooth rod specifications |

customizable |

||||

|

Environmental Conditions |

Outdoor, no more than 4500m above sea level, temperature -45~+50℃ |

|

||||

Downhole Progressive Cavity Pump

The downhole cavity pump consists of a rotor and a stator. The rotor is the only moving part in the cavity pump. It is made of high-strength steel after finishing and the surface is chrome plated; the stator is made by molding high elastic synthetic rubber in the steel pipe, according to different Application can choose a variety of rubber types.

Cavity Pump Advantages

Heavy oil, cold sand mining; inclined shaft, partial wear treatment.

Heavy oil, cold sand mining; inclined shaft, partial wear treatment.

Anti-corrosion treatment; high efficiency, energy saving; narrow space production, low noise.

Anti-corrosion treatment; high efficiency, energy saving; narrow space production, low noise.

Improve residential environment.

Improve residential environment.

PC pump Specifications

|

Model |

Rated Displacement |

Lifting Capacity |

||||

|

ml/r |

m3/d·r |

bbl/d·r |

Grade |

Height m |

Height Ft |

|

|

40-21 40-27 40-42 |

40 |

0.057 |

0.36 |

21 27 42 |

960 1200 1900 |

3100 3900 6200 |

|

75-21 75-27 75-40 |

75 |

0.108 |

0.68 |

21 27 40 |

960 1200 1800 |

3100 3900 5900 |

|

120-27 120-36 120-40 |

120 |

0.173 |

1.09 |

27 36 40 |

1200 1600 1800 |

3900 5200 5900 |

|

190-27 190-33 190-40 |

190 |

0.274 |

1.72 |

27 33 40 |

1200 1500 1800 |

3900 4900 5900 |

|

300-21 300-27 |

300 |

0.432 |

2.72 |

21 27 |

960 1200 |

3100 3900 |

|

400-20 400-30 |

400 |

0.576 |

3.62 |

20 30 |

910 1300 |

2900 4200 |

|

500-14 500-21 |

500 |

0.720 |

4.53 |

14 21 |

640 960 |

2100 3100 |

|

600-14 600-21 |

600 |

0.864 |

5.43 |

14 21 |

640 960 |

2100 3100 |

|

800-16 |

800 |

1.152 |

7.25 |

16 |

730 |

2400 |

|

1100-10 1100-12 1100-14 1100-16 |

1100 |

1.584 |

9.96 |

10 12 14 16 |

460 550 640 730 |

1500 1800 2100 2400 |

|

1400-14 |

1400 |

2.106 |

12.7 |

14 |

640 |

2100 |

|

1600-12 |

1600 |

2.304 |

14.5 |

12 |

550 |

1800 |

|

230DT27(120DT33) 230DT40(180DT33) 230DT50(230DT33) |

230 |

0.331 |

2.08 |

27 40 50 |

1200 1800 2300 |

3900 5900 7500 |

|

375DT27(120DT54) 375DT33(150DT54) 375DT40(180DT54) |

375 |

0.540 |

3.40 |

27 33 40 |

1200 1500 1800 |

3900 4900 5900 |

|

460DT27(120DT66) 460DT33(150DT66) |

460 |

0.660 |

4.17 |

27 33 |

1200 1500 |

3900 4900 |

|

580DT18(080DT83) 580DT21(090DT83) 580DT27(120DT83) 580DT33(150DT83) |

580 |

0.835 |

5.25 |

18 21 27 33 |

820 960 1200 1500 |

2700 3100 3900 4900 |

|

800DT20(090DT110) |

800 |

1.152 |

7.25 |

20 |

910 |

2900 |

|

990DT14(060DT142) |

990 |

1.426 |

8.97 |

14 |

640 |

2100 |

|

1200DT16(070DT174) 1200DT21(090DT174) |

1200 |

1.728 |

10.9 |

16 21 |

730 960 |

2400 3100 |

|

2000DT16(070DT290) |

2000 |

2.880 |

18.1 |

16 |

730 |

2400 |