Special Alloy Anti-Scale Systems (SAAS) represent a cutting-edge solution for combating scale formation in industrial operations. Leveraging advanced multi-element alloys, SAAS offers unparalleled performance in preventing scale deposition on equipment and surfaces exposed to harsh operating conditions. By incorporating proprietary anti-scale technology, SAAS effectively inhibits the nucleation and growth of scale crystals, thereby maintaining equipment efficiency and prolonging operational lifespan.

Technical Mechanism

Through unique alloy composition design and strict smelting preparation control, numerous insoluble and uniform micro battery systems are formed in the microstructure of the anti-scaling alloy. Solid-liquid-electron interaction occurs during full contact with the fluid, thus regulating the physical characteristics of the fluid, affecting the nucleation and growth process of the scaling crystal, changing the adhesion and dispersion performance of the scaling, and playing an excellent scale inhibition performance; At the same time, after the anti-scaling alloy contacts with water, the change of physical parameters such as surface tension makes the formed old scale dissolve; After the anti-scaling alloy contacts with the fluid, it can greatly reduce the generation of scaling and avoid corrosion under the scale (such as alkali corrosion, acid corrosion, etc.), thus playing a significant role in corrosion prevention.

Through unique alloy composition design and strict smelting preparation control, numerous insoluble and uniform micro battery systems are formed in the microstructure of the anti-scaling alloy. Solid-liquid-electron interaction occurs during full contact with the fluid, thus regulating the physical characteristics of the fluid, affecting the nucleation and growth process of the scaling crystal, changing the adhesion and dispersion performance of the scaling, and playing an excellent scale inhibition performance; At the same time, after the anti-scaling alloy contacts with water, the change of physical parameters such as surface tension makes the formed old scale dissolve; After the anti-scaling alloy contacts with the fluid, it can greatly reduce the generation of scaling and avoid corrosion under the scale (such as alkali corrosion, acid corrosion, etc.), thus playing a significant role in corrosion prevention.

Key Features

1. Advanced Multi-Element Alloys: SAAS utilizes specialized alloys engineered to resist scale formation and corrosion, ensuring superior performance in challenging environments.

2. Proprietary Anti-Scale Technology: SAAS technology disrupts scale crystal formation through the unique interaction of the alloy's microstructure with the fluid, preventing scale deposition and promoting the smooth operation of equipment.

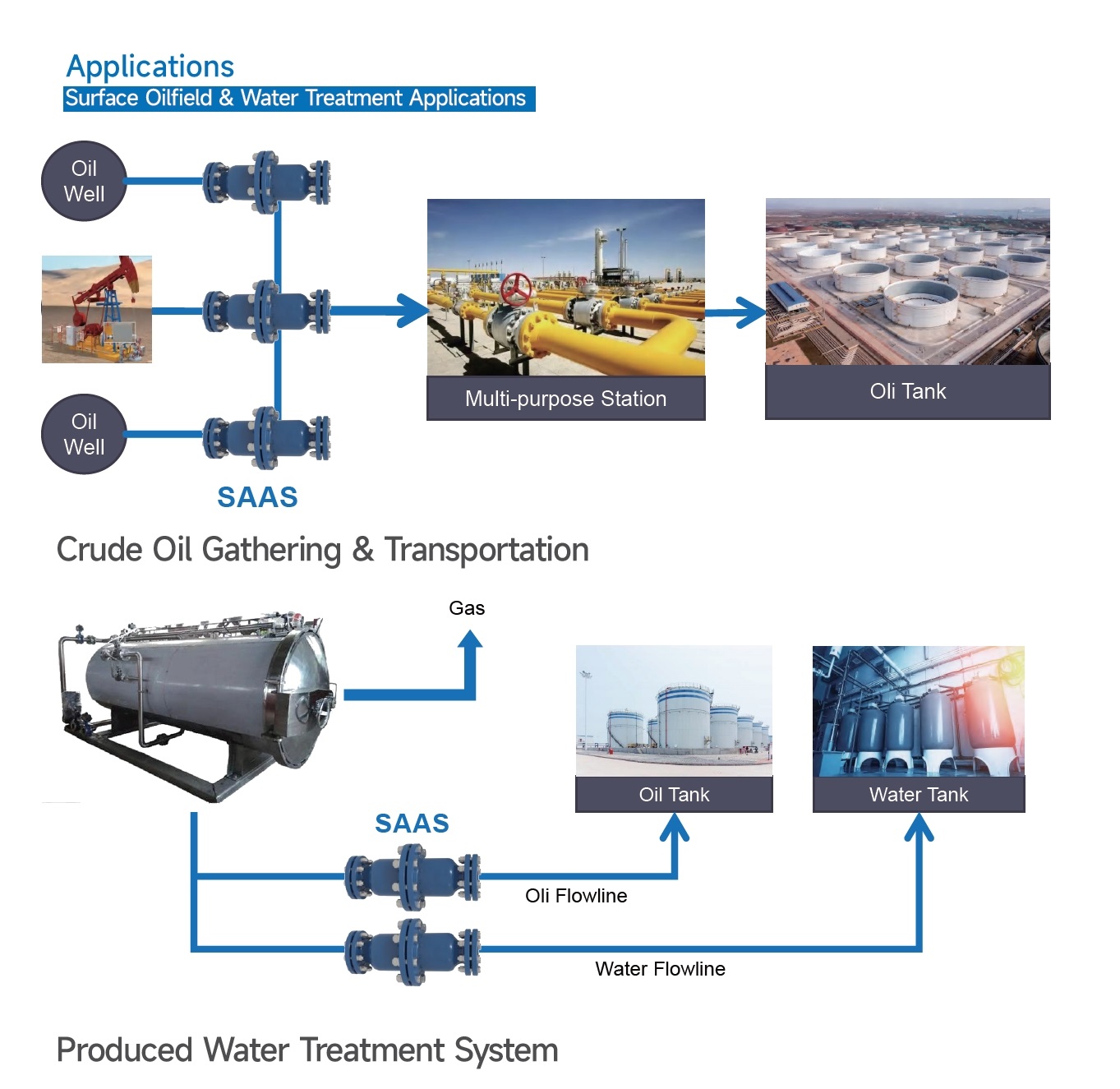

3. Versatile Application: SAAS is suitable for a wide range of industries, including oil and gas production, water treatment, power generation, chemical processing, and mining, where scale deposition poses operational challenges.

4. Enhanced Operational Efficiency: By mitigating scale formation, SAAS helps maintain optimal equipment performance, reducing downtime, and minimizing maintenance costs.

5. Environmental Sustainability: SAAS contributes to environmental sustainability by reducing the use of chemical scale inhibitors and minimizing the need for harsh cleaning chemicals, thus promoting a greener approach to industrial operations.

Benefits

Reduced Downtime: By preventing scale buildup, SAAS reduces the frequency and duration of maintenance shutdowns.

Lower Maintenance Costs: Reduced scaling leads to less frequent cleaning and maintenance, saving labor and operational costs. Extended Lifespan: By minimizing scale formation, SAAS helps extend the lifespan of equipment and pipelines, reducing the need for replacements.

Reduced Corrosion: Special alloys often resist corrosion better, further protecting equipment.

Reduced Chemical Usage: SAAS often reduces the need for chemical descaling agents, leading to fewer chemicals being discharged into the environment.

Regulatory Compliance: Many industries have strict regulations regarding scaling and water treatment. SAAS helps companies meet these standards more easily.